BEKA AZU

Oil Lubrication Pump

ABOUT

BEKA AZU

Compact. Precise. Eco-Friendly

The BEKA AZU is a robust, mechanically or electrically driven oil lubrication pump designed for continuous chain lubrication. Ideal for agricultural, industrial, and recycling applications, it ensures optimal performance by delivering precise lubrication while the machinery is in operation.

Features

- Up to 12 lubrication points Configure with up to 6 individual outlets or 12 paired outlets, allowing tailored lubrication for various applications.

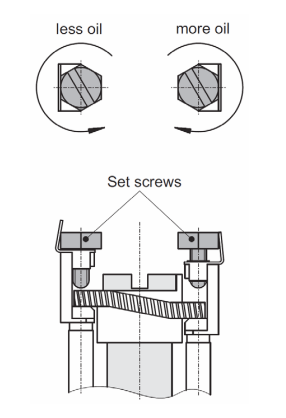

- Adjustable feed rates Each lubrication point's feed rate can be individually adjusted via set screws, ensuring precise oil delivery.

- Lubrication during operation Applies lubricant while chains are in motion, reducing wear and preventing over-lubrication and dripping.

- Versatile drive options Available with mechanical, hydraulic, or electric drives (12V DC, 24V DC, 200/240V AC, or 346/420V AC) to suit diverse machinery requirements.

- Compact design Requires minimal mounting space, making it suitable for installations with space constraints.

- Pre-assembled systems available Can be delivered fully assembled with predefined lines and lengths, facilitating easy installation.

BEKA AZU Oil Lubrication Pump Operation & Manual

Installed and Working Hard

Shown here fitted to a baler, the BEKA AZU pump delivers reliable oil lubrication directly to the moving chain components while in operation. Its compact footprint makes it ideal for agricultural machinery where space is limited but performance is critical. Less wear, less downtime — more time in the field.

Contact usBEKA AZU

HOW IT WORKS

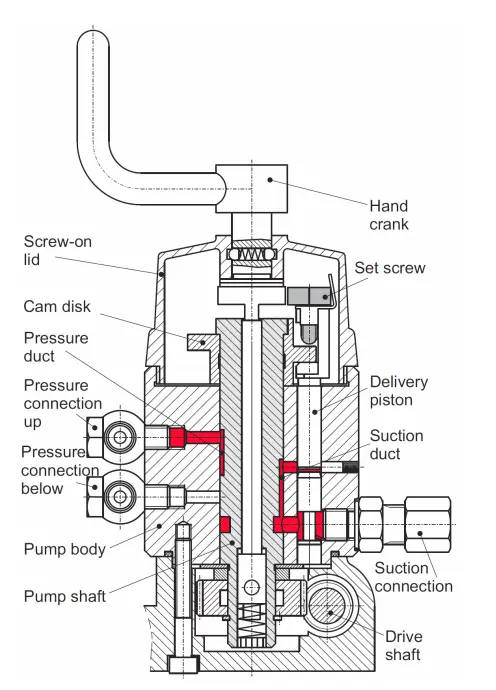

The AZU pump operates with a rotating drive shaft that activates up to six delivery pistons in a circular configuration. These pistons draw oil from a connected reservoir and then deliver it under pressure to the lubrication points. Each piston stroke ensures accurate oil delivery, and the output can be adjusted individually (for up to 6 outlets) or in pairs (for 7–12 outlets).

A hand crank option is available for pre-lubrication, which helps fill long lines before system startup. Output levels are set using adjustment screws located under a screw-on lid, with each turn reducing delivery volume by approximately 25%.

This smart and efficient mechanism ensures clean, consistent lubrication during machine operation — reducing wear and keeping equipment running smoothly.

Inside the AZU Pump

This cross-sectional view of the BEKA AZU pump shows the internal drive system that powers the delivery pistons. As the drive shaft rotates, it activates a cam disk that creates suction and pressure strokes, drawing oil from the reservoir and pushing it precisely to each lubrication point.

Easy Output Adjustment

Adjusting the lubrication output is as simple as turning a set screw. Clockwise increases oil flow, counterclockwise reduces it. The pump comes factory-set to full stroke, and you can fine-tune delivery per outlet using the access lid, no tools required beyond a standard driver.

IDEAL FOR THESE

APPLICATIONS

The BEKA AZU is ideal for

- Agricultural machinery (e.g., balers, spreaders)

- Industrial equipment (e.g., compressors, printing presses, chain conveyors)

- Recycling machinery

- Port equipment

BEKA AZU

TECHNICAL SPECIFICATIONS

BEKA OIL

PUMP COMPARISON

Need help choosing the right pump?

Contact our team for tailored advice on the best BEKA system for your machine.